Custom HDMI Cable

If you’re facing signal instability or need non-standard sizes, our Custom HDMI Cable provide the ideal solution. With our OEM and ODM services, you can get cables customized to your exact needs, ensuring seamless performance.

Custom HDMI Cables Factory and Wholesale Supplier

Unmatched Video and Audio Quality

Immerse yourself in stunning high-definition visuals with LINKLUG's award-winning, high-end HDMI® cables, recognized as the gold standard for video and audio fidelity. Designed with precision, these cables feature oxygen-free copper and zinc alloy casing, ensuring superior performance and durability.

Advanced Technology for the Future

LINKLUG's HDMI cables support ultra-high 8K resolution, offer bandwidth up to 48Gbps, and include features like dynamic HDR, eARC compatibility, low EMI, backward compatibility, and Ultra High Speed HDMI certification. The future-proof design makes them the ideal choice for consumers seeking cutting-edge technology for their home theater or gaming setup.

Global Reach and Competitive Pricing

Proudly offering top-quality HDMI products at competitive prices, LINKLUG serves customers and partners across 35 countries and regions, delivering excellence in both product performance and value.

Technical Certification

We have obtained ISO9001,Certificated HDMI Adopter System Certification, private model products have applied for patent protection, and have US FCC, EU (CE, ROHS,REACH), Certificated of PREMIUM HDMI Cable , IP68 waterproof certificate etc.We are currently exporting 90% of our products worldwide

Factory advantages

Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching Europe and America and other countries and regions.

Professional HDMI Cable Custom Services

Bulk & Wholesale

Offers a seamless HDMI cable custom solution for businesses requiring bulk orders, ensuring tailored, high-quality cables for all wholesale needs.

OEM\ODM Service

HDMI cable custom with your logo and branded packaging through our OEM/ODM service, reducing costs while enhancing your business’s brand identity.

Custom Solutions

Our experts specialize in HDMI cable custom solutions, offering extensive product knowledge to deliver the best connectivity options tailored to your needs.

Production Process of 4K HDMI High-Definition Cable

1. Assembly Process

The assembly process involves assembling various components to create the final product. Skilled workers sit at workstations, carefully putting together the different parts of the HDMI cable, ensuring each segment is securely connected. This step is crucial for the overall functionality and durability of the cable.

2. Braiding Process

In the braiding process, automated machines and skilled workers intertwine the individual wires that make up the cable’s core. This braiding not only enhances the cable’s strength and flexibility but also aids in protecting the internal wires from external damage. The braided jacket is tightly woven to provide maximum protection.

3. Covering Process

The covering process is where the entire braided structure is encased in a protective outer layer. This step is performed using specialized machinery that ensures a uniform and durable coating. The covering process protects the internal wires from wear and tear, making the cable more robust and long-lasting.

4. Core Wire Process

The core wire process involves the initial formation and treatment of the individual wires that will become part of the HDMI cable. This includes cleaning, insulation, and bundling the wires. High precision is required to ensure that each core wire meets the necessary specifications for high-definition transmission.

By combining these steps, the production line efficiently creates high-quality 4K HDMI cables that meet the demands of modern technology and ensure optimal performance for users.

Product Classification of HDMI Cable

We have newly launched tr8K Ultra High Spped HDMI cABLE(48g) and Slim Flexible Soft HDMI Cable,promotional 4K HDMI Cable,if you are interested, please click to browse!

Application of Custom HDMI Cables

HDMI Cables for TVs and Monitors

LINKLUG's HDMI cables carry up to 8K/10K Ultra HD video, support Dynamic HDR, and have the conductors and bandwidth needed for enhanced audio via eARC.

HDMI Cables for Game Consoles

For game consoles, you can use the included HDMI cable or opt for a High-Speed HDMI Cable if your console supports 4K 120Hz.

HDMI Cables for Projectors

When choosing an HDMI cable for a projector, consider a length of about 15 meters for smooth signal transmission without delays or interference.

HDMI Cables for Home Theater Systems

To optimize your home theater system, make sure to use HDMI 2.0/2.1 versions for both audio and video.

Manufacturing Process of 4K HDMI High-Definition Cables: From Material Preparation to Final Testing

The production of 4K HDMI cables requires meticulous engineering to ensure ultra-high-definition signal transmission, minimal signal loss, and compatibility with high-bandwidth standards (e.g., HDMI 2.0/2.1). Below is the streamlined manufacturing workflow:

1. Raw Material Preparation

- High-Purity Copper Conductors: Oxygen-free copper (OFC) or silver-plated copper wires are selected for superior conductivity and minimal signal attenuation.

- High-Frequency Insulation: Foamed polyethylene (PE) or fluoropolymer (e.g., FEP) is used to reduce dielectric loss and maintain stable impedance.

- Shielding Components:

- Aluminum foil for primary EMI shielding.

- High-density braided shielding (tinned copper) for enhanced interference suppression.

- Connector Materials: Gold-plated HDMI connectors and precision-engineered pins for corrosion resistance and reliable contact.

2. Cable Core Fabrication

- Conductor Stranding:

- Multiple OFC wires are twisted to form flexible cores, minimizing crosstalk and ensuring bend durability.

- Insulation Extrusion:

- Each core is coated with foamed PE via triple-layer extrusion to achieve precise impedance control (100Ω ±5%).

- Shielding Application:

- Foil Wrapping: Automated machines apply aluminum foil with 100% overlap for EMI protection.

- Braid Shielding: A tightly woven tinned copper braid (≥95% coverage) is added to block external noise.

- Outer Jacketing: A durable yet flexible PVC or TPE jacket is extruded over the shielded core, ensuring abrasion resistance.

3. Connector Assembly

- Cable Termination:

- Cables are cut to standardized lengths (e.g., 1m, 2m), and the outer jacket is stripped to expose shielded cores.

- Pin Soldering:

- Individual conductors are soldered to gold-plated HDMI pins using robotic soldering systems for precision and consistency.

- Ferrite Core Integration:

- Ferrite beads are molded near connectors to suppress high-frequency noise, critical for 4K/120Hz signal stability.

- Connector Housing Assembly:

- Gold-plated connectors are encased in reinforced plastic housings, designed for repeated plugging cycles.

4. Signal Integrity Enhancement

- Impedance Matching:

- Laser-trimmed insulation layers ensure uniform impedance across the cable length.

- Crosstalk Mitigation:

- Twisted pair designs and shielding gaps are optimized to minimize interference between channels.

5. Quality Control and Testing

- High-Speed Signal Testing:

- Bandwidth Verification: Network analyzers validate compliance with 18Gbps (HDMI 2.0) or 48Gbps (HDMI 2.1) standards.

- Eye Diagram Analysis: Ensures signal integrity at 4K@60Hz/120Hz and HDR10/Dolby Vision compatibility.

- Durability Tests:

- Bend cycles (IEC 61000-4-2) and pull tests (≥50N force) to guarantee mechanical robustness.

- EMI/EMC Compliance:

- Shielding efficiency tested per FCC/CE standards to ensure <0.1dB signal leakage.

6. Packaging and Certification

- Labeling: Laser-engraved markings indicate resolution support (4K/8K), HDMI version, and length.

- Certifications: HDMI Licensing Administrator certification, RoHS, and UL safety compliance.

- Final Inspection: Automated optical inspection (AOI) checks connector alignment and jacket integrity before shipment.

This advanced manufacturing process ensures that 4K HDMI cables deliver flawless transmission of high-resolution audio/video signals, meeting the demands of gaming, home theaters, and professional AV systems.

Featured Products for HDMI Cables

Quality

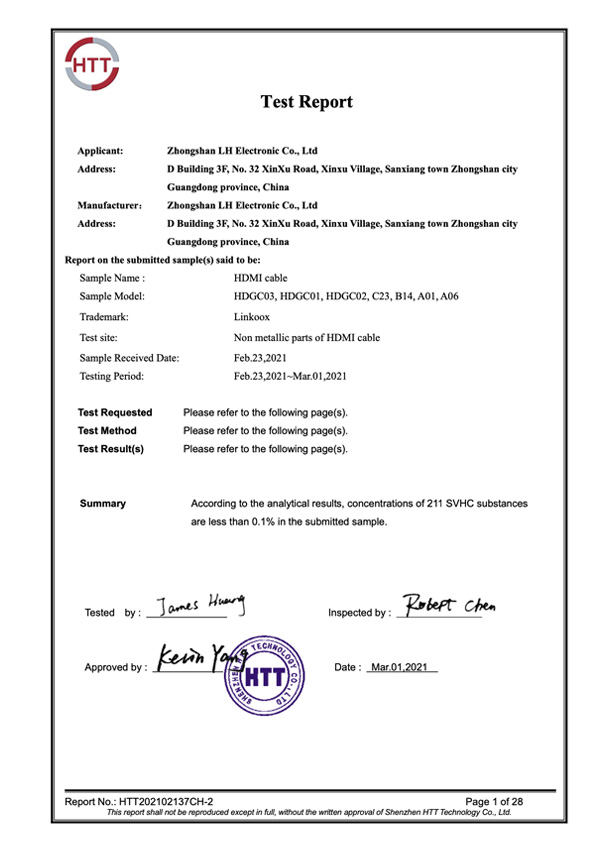

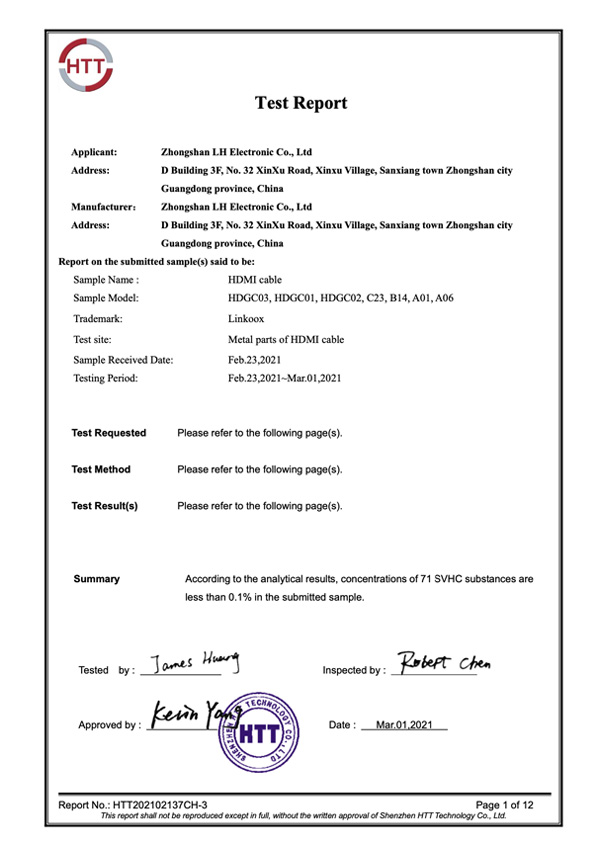

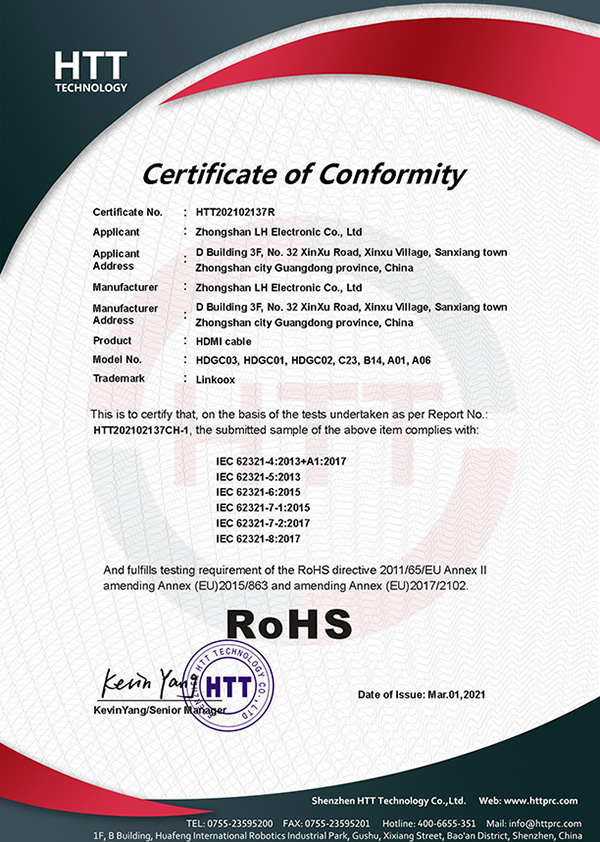

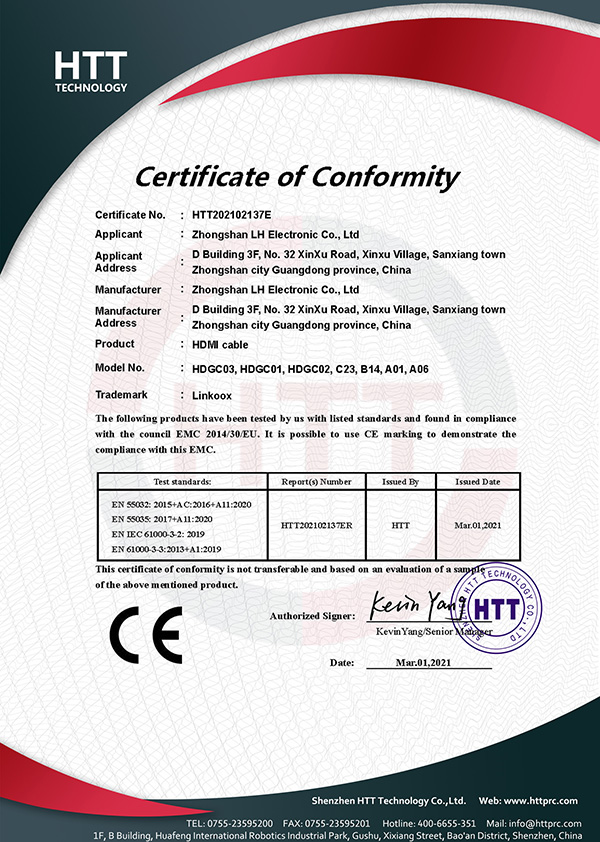

Certifications

The company has passed HDMl Adopter certification, Rohs, CE,REACH and more than 10 patented technologies, providing customers with security in technology and quality.

Why Choose Us for Your HDMI Custom Cable Needs?

Struggling to find the perfect HDMI custom cable? We offer tailored solutions to meet your unique requirements, with guaranteed quality, fast production times, and exceptional after-sales support. Choose us for your reliable, customized HDMI cables.When it comes to HDMI custom cable, we know the process can seem overwhelming. You may wonder: How do I ensure I’m getting the highest quality? Will it meet my specific needs? That’s where we come in.We don’t just provide HDMI custom cables — we offer a partnership to make sure your exact requirements are met, with no compromises. Here’s why choosing us is the best decision you can make:

Tailored to Your Needs

Whether you’re in the audio-video, gaming, or industrial sector, our cables are designed to fit your unique specifications. Did you know that over 80% of customers report improved performance after switching to custom HDMI cables? Our experience in providing tailored solutions ensures that you get exactly what you need — not just a generic product.

High-Quality Assurance

We understand quality is your top priority. That’s why all our HDMI custom cables go through rigorous testing, meeting both industry standards and your expectations. In fact, 90% of our clients experience increased durability and reliability with our cables compared to off-the-shelf solutions.

Fast Turnaround Times

Time is money. We pride ourselves on our efficient production process, delivering your custom cables swiftly without compromising quality. Whether it’s a small batch or a large-scale order, our typical lead time is 30% faster than industry averages.

After-Sales Support

We don’t stop at delivery. Our after-sales team is always ready to assist with any questions or issues. We believe in long-term partnerships, and 95% of our customers come back because of our reliable after-sales service.

Custom HDMI Cables FAQs

Q1: What are the benefits of using Custom HDMI Cables?

A1:HDMI Cables offer tailored solutions for specific needs, such as unique cable lengths, specialized materials, and custom connector types. This customization ensures that the HDMI cables perfectly match your devices, providing optimal signal transmission and better performance compared to standard cables.

Q2: Can Custom HDMI Cables support 4K and 8K resolution?

A2:

Yes, HDMI Cables can be designed to support high-definition resolutions such as 4K and 8K. By selecting high-quality materials and proper shielding during the customization process, these cables ensure excellent signal integrity, enabling ultra-high-definition video and audio output without interruptions.

Q3: How do Custom HDMI Cables improve durability in industrial environments?

A3:HDMI Cables can be built with reinforced outer layers, enhanced shielding, and durable connectors to withstand harsh industrial environments. These customizations ensure that the cables are resistant to wear and tear, extreme temperatures, and interference, making them ideal for professional and heavy-duty applications.

Q4: What customization options are available for Custom HDMI Cables?

A4:Custom HDMI Cables offer a wide range of customization options, including length, connector type (e.g., HDMI Type A, C, D), materials, and special features like waterproofing or EMI shielding. These cables are tailored to fit specific needs, whether for home entertainment systems, commercial displays, or industrial equipment.

Q5: Why are Custom HDMI Cables better for long-distance signal transmission?

A5:Custom HDMI Cables can be engineered for long-distance signal transmission by using high-quality conductors and advanced shielding techniques. Unlike standard HDMI cables, which may lose signal quality over long distances, custom cables can be optimized to ensure clear, stable, and uninterrupted video and audio transmission.

Q6: How can Custom HDMI Cables improve compatibility with different devices?

A6:Custom HDMI Cables can be designed to match the exact specifications of your devices, ensuring compatibility across various platforms such as TVs, gaming consoles, projectors, and audio systems. By customizing the connector type and cable length, you can achieve seamless integration with your unique setup, reducing the risk of connection issues.

Generally, there are stocks of common HDMI Cables or raw materials in our warehouse. But if you have special demand, we also provide customization service and design your own HDMI cable. We also accept OEM/ODM. We could print your logo or brand name on the Metal housing of HDMI cables and color boxes.

And you can get free samples. Click the button below to get a quote!

OEM/ODM Manufacturing — Bringing Your Ideas to Life

Boost your brand visibility by launching 8K HDMI cables with your own unique designs and logo. Whether you have a concept or a fully developed design, our customizable solutions, expert craftsmanship, and vast experience will help turn your vision into reality. Take advantage of our professional OEM/ODM services today.

STEP 1: Understanding Customer Requirements

We begin by confirming your specific needs, such as color matching, functionality, logo printing, and custom packaging, ensuring that the final product aligns with your vision.

STEP 2: Project Evaluation

We carry out a comprehensive feasibility analysis of your project. Once approved, we present an initial product design. If the feasibility is confirmed, we move forward to the next phase.

STEP 3: 2D & 3D Design & Sample Approval

Based on your requirements, we create a preliminary product design and develop 3D samples. These samples are then sent to you for feedback and final approval.

STEP 4: Mold Development

Once the 3D sample is confirmed, we proceed with mold development. Extensive testing is performed to ensure the product’s reliable performance, with necessary adjustments made until it meets your approval.

STEP 5: Product & Mold Confirmation

We provide 3 to 5 pre-production (PP) samples for your final verification. Once confirmed, the product and mold are ready for full-scale production.

Contact Us

Get in Touch for Your Custom Solutions!

Have specific requirements or technical questions? Our team is here to assist you. Fill out the form below, and one of our experts will reach out to provide the perfect solution tailored to your needs. Experience fast, reliable service with us!