Converter Factory

Looking for a trusted HDMI Converter factory? We offer

high-quality, customizable HDMI converters tailored to

meet your business needs, ensuring durability,

performance, and fast delivery.

Solutions for Your HDMI Converter Needs - Professional Converter Factory

High Compatibility for Diverse Applications

We understand that your projects vary widely, so we offer HDMI converters with high compatibility to suit diverse devices and applications. Through our custom HDMI cables, we can tailor solutions to your specific requirements, helping you stay agile and adaptable in a changing market.

Technical Support for Quality and Performance

Quality and reliability are our top priorities. We offer dedicated technical support to ensure each product meets stringent quality standards in design and manufacturing. With our custom HDMI cables, you receive high-performance product support, delivering stability and premium experiences for your clients

Fast Customization for Unique Client Needs

As a flexible converter factory, we provide fast customization services to meet the diverse needs of our clients. Whether it’s unique specifications or custom designs, our team responds swiftly to your requests, helping you achieve your project goals more efficiently.

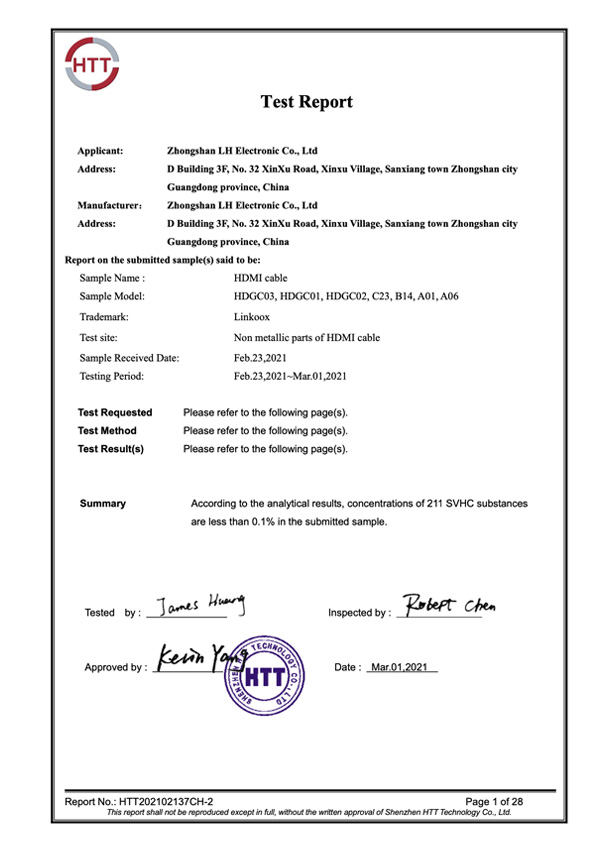

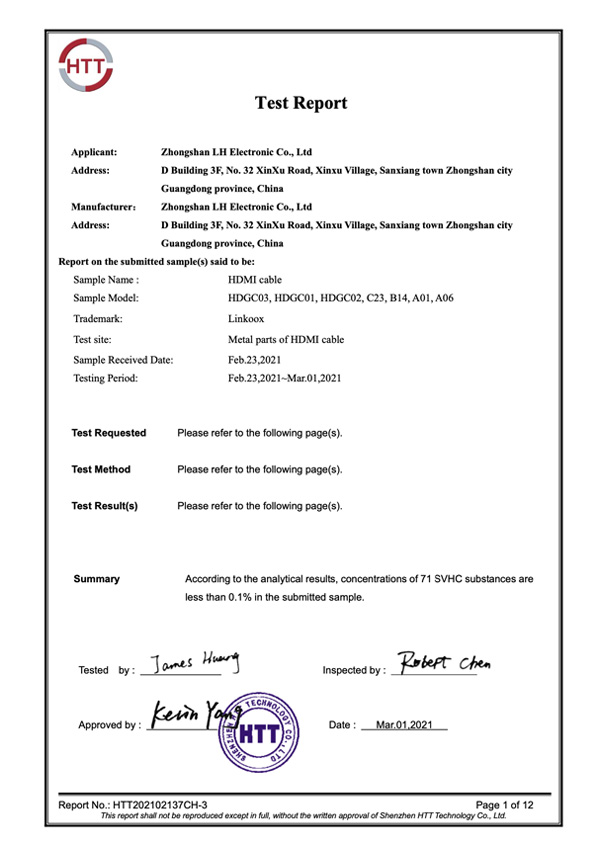

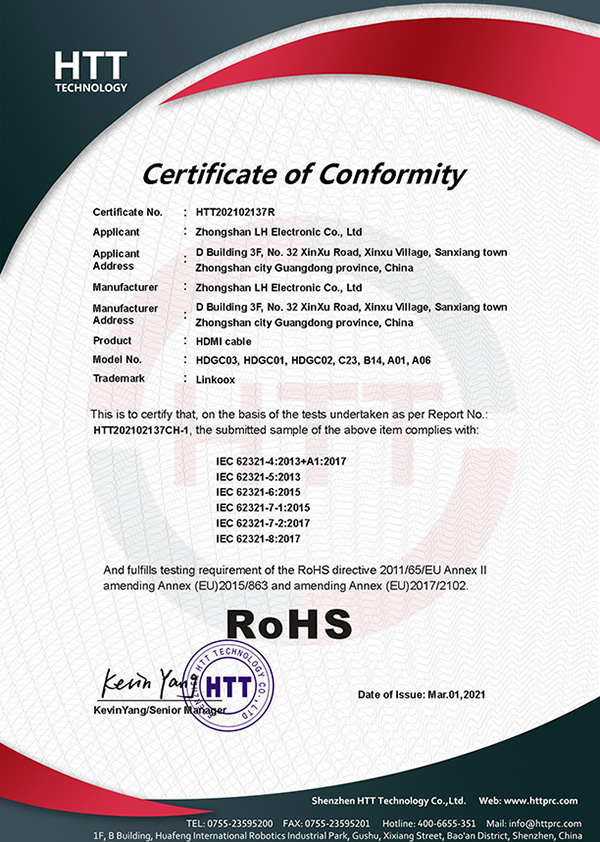

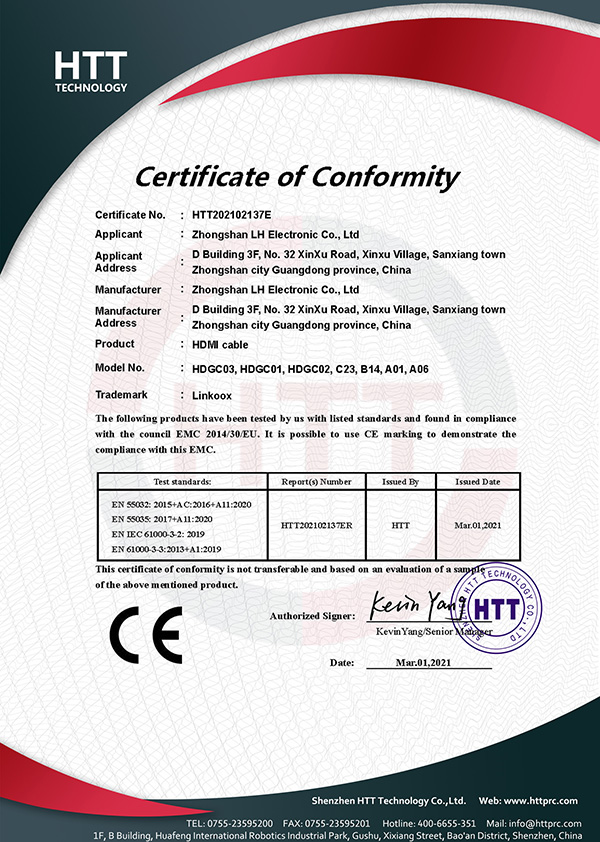

Technical Certification

e have obtained ISO9001,Certificated HDMI Adopter System Certification, private model products have applied for patent protection, and have US FCC, EU (CE, ROHS,REACH), Certificated of PREMIUM HDMI Cable , IP68 waterproof certificate etc.We are currently exporting 90% of our products worldwide.

Factory advantages

Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching Europe and America and other countries and regions.

Your Reliable HD Converter Factory Partner for Seamless Connectivity Solutions

Bulk & Wholesale

If you require a steady, reliable supply of HD converters, we’ve got you covered. As an established HD converter factory, we offer bulk and wholesale services tailored to meet your high-volume demands without compromising on quality. We understand that businesses need both affordability and reliability, especially when purchasing at scale.

With our optimized manufacturing processes, we can fulfill large orders quickly and cost-effectively, ensuring you receive products on time. Our bulk service means you’re able to secure a consistent supply of high-quality HD converters that meet industry standards, keeping your operations running smoothly.

OEM\ODM Service

Your brand is unique, and your converters should reflect that. With our comprehensive OEM and ODM services, we offer flexibility in design, functionality, and branding. As your HD converter factory partner, we collaborate with you to create products that align with your brand identity and meet your specifications.

From custom logos to specialized functions, we provide end-to-end support in developing HD converters that resonate with your target market. With our OEM/ODM expertise, you can be confident that your products will stand out in the marketplace while maintaining the performance and reliability you expect.

Custom Solutions

Some projects require more than just off-the-shelf products. That’s why we offer custom solutions that are precisely crafted to meet the unique needs of your applications. As a dedicated HD converter factory, we prioritize understanding your requirements, so we can develop converters with the exact features, connectivity options, or configurations you need.

Whether it’s specialized input/output compatibility, size adjustments, or enhanced performance, our custom solutions ensure that your converters perfectly fit your system or project requirements. We’re here to provide solutions that make a real difference in your workflow and user experience.

Product Classification of HDMI Converter

Manufacturing Process of HDMI Male-to-Female Adapters: From Component Assembly to Quality Assurance

1. Raw Material Procurement

- HDMI Connectors: High-grade male (plug) and female (receptacle) HDMI connectors with gold-plated contacts for optimal conductivity.

- PCB (Printed Circuit Board): Custom-designed circuit boards to route HDMI signals between connectors.

- Shielding Components: EMI-resistant metal shielding layers (e.g., aluminum or steel) to minimize interference.

- Housing Materials: Durable ABS or zinc alloy for the adapter’s outer casing, ensuring heat resistance and mechanical strength.

- Internal Wiring: High-speed HDMI-compliant copper wires for signal integrity.

2. PCB Assembly

- SMT (Surface Mount Technology): Automated placement of micro-components (resistors, capacitors, ICs) onto the PCB to manage signal conversion and amplification.

- HDMI Signal Routing: Precision etching of PCB traces to align with HDMI 2.0/2.1 specifications (e.g., 18Gbps bandwidth).

- Shielding Layer Integration: Attaching EMI shielding materials to the PCB to protect against external interference.

3. Connector Installation

- Male Connector Assembly:

- Soldering the male HDMI plug’s pins to the PCB using reflow soldering for high-speed signal integrity.

- Securing the connector with epoxy resin for strain relief.

- Female Connector Assembly:

- Mounting the female HDMI receptacle onto the PCB, ensuring alignment with male plug specifications.

- Reinforcing joints with mechanical fasteners to withstand repeated plugging/unplugging.

4. Housing and Final Assembly

- Injection Molding: Forming the adapter’s outer casing using ABS or zinc alloy molds for heat and impact resistance.

- Internal Component Encapsulation: Sealing the PCB and connectors within the housing using snap-fit or screw-fastening mechanisms.

- Strain Relief Design: Adding rubberized boots or reinforced joints at cable entry points to prevent wire fraying.

5. Quality Testing and Certification

- Signal Integrity Testing:

- Validating bandwidth (e.g., 4K@60Hz, HDR) using HDMI compliance testers (e.g., Quantum Data or VESA tools).

- Checking for crosstalk, jitter, and latency issues.

- Durability Testing:

- Plug/unplug cycle tests (5,000+ cycles) to ensure connector longevity.

- Bend and torsion tests on the housing and strain relief components.

- Environmental Testing:

- Exposure to high/low temperatures, humidity, and vibration to simulate real-world conditions.

- Certification: Compliance with HDMI Licensing LLC standards and RoHS/CE/FCC regulations.

6. Packaging and Shipment

- Anti-Static Packaging: Individual adapters are wrapped in ESD-safe bags to prevent electrostatic damage.

- Labeling: Each unit is labeled with technical specs (HDMI version, bandwidth, certifications).

- Bulk Packaging: Units are packed into retail-ready boxes or bulk cartons with user manuals and warranty cards.

- Global Distribution: Ready for shipment to electronics retailers, OEM partners, or end-users.

Key Features Ensured by the Process:

- High-Speed Performance: Supports HDMI 2.0/2.1 standards for 4K/8K video and immersive audio.

- Robust Build: Reinforced housing and gold-plated contacts resist corrosion and wear.

- Plug-and-Play Compatibility: Universally compatible with TVs, gaming consoles, PCs, and AV equipment.

This streamlined production process guarantees that HDMI male-to-female adapters deliver reliable connectivity and meet the demands of modern home theaters, offices, and multimedia setups.

We have newly launched USB3.0 to Sata Converter and HDMI Y Splitter 3 in 1 ,Micro HDMI male to HDMI female converter,if you are interested, please click to browse!

Versatile Solutions from Your HD Video Converter Factory Pro Full Service

Broadcasting: Smooth, Real-Time Video Processing

In the fast-paced world of broadcasting, quality and speed are critical. Our HD video converters are optimized for real-time processing, ensuring high-quality image transmission with minimal latency. As a trusted HD video converter factory pro full provider, we offer solutions with advanced encoding and decoding capabilities, perfect for live broadcasts, sports events, and more. With our converters, broadcasters gain the reliability and efficiency they need to keep audiences engaged without any disruption.

Education: Enhancing Interactive Learning

Experiences

Modern education relies heavily on high-quality video content, whether it’s for virtual classes, webinars, or interactive displays in classrooms. Our HD video converters ensure sharp, clear visuals that are crucial for effective learning. Built with user-friendly interfaces and adaptable connectivity, our converters make it easy to integrate video seamlessly across various devices and setups. By partnering with our HD video converter factory pro full services, educational institutions can enhance their digital learning environments with reliable, high-quality video solutions

Corporate Environments: Seamless Video for

Presentations and Conferences

In corporate settings, video quality can impact the effectiveness of presentations and video conferencing. Our HD video converters ensure that visuals are clear and professional, making your communications impactful. With a range of input and output compatibility options, our converters support everything from high-resolution displays to multiple screens, enhancing collaboration and productivity. Choosing our HD video converter factory pro full service ensures that your corporate AV setup remains smooth, adaptable, and professional.

Home Theater: Elevating the Home Entertainment

Experience

For home theater enthusiasts, high-quality video output is key to an immersive experience. Our HD video converters deliver cinema-quality visuals by optimizing video resolution and audio synchronization, bringing your favorite movies and shows to life. Designed for easy integration with home entertainment systems, our converters are the perfect addition for those seeking superior viewing experiences. With our HD video converter factory pro full solutions, you can trust that every detail of your home theater setup is covered, giving you the best in video quality.

Featured Products for Converters

Materials and Structural Composition of HDMI Male-to-Female Adapters

The HDMI male-to-female adapter is engineered with high-quality materials to ensure reliable signal transmission, durability, and compatibility. Below is a detailed breakdown of its key components and material specifications:

1. Connectors

Male HDMI Plug:

- Shell Material: Zinc alloy or stainless steel for corrosion resistance and mechanical strength.

- Contact Pins: 19 gold-plated copper pins (for HDMI Type A) to ensure low resistance, oxidation resistance, and stable conductivity.

- Insulation: High-temperature-resistant nylon or thermoplastic (e.g., PBT) to prevent short circuits.

Female HDMI Receptacle:

- Housing: Nickel-plated brass or reinforced polymer for durability and EMI shielding.

- Internal Contacts: Gold-plated spring-loaded pins to maintain secure connections with male plugs.

2. Printed Circuit Board (PCB)

- Substrate: FR-4 fiberglass laminate for heat resistance and electrical insulation.

- Traces: High-purity copper traces etched to HDMI 2.0/2.1 specifications, supporting bandwidths up to 18Gbps (4K@60Hz) or 48Gbps (8K@60Hz).

- SMT Components:

- Micro-resistors and capacitors for signal conditioning.

- IC chips (e.g., signal repeaters or equalizers) to boost signal integrity over long distances.

3. Shielding and EMI Protection

- Metal Shielding Layer: Aluminum or tin-plated steel foil wrapped around internal components to block electromagnetic interference (EMI).

- Ferrite Beads: Integrated near connectors to suppress high-frequency noise.

4. Outer Housing

- Material: ABS (Acrylonitrile Butadiene Styrene) or zinc alloy for impact resistance, heat dissipation, and lightweight design.

- Surface Finish: Matte or glossy texture with laser-etched HDMI logos and version indicators.

- Strain Relief: Reinforced rubber or thermoplastic elastomer (TPE) at cable joints to prevent bending damage.

5. Internal Wiring

- Conductors: Oxygen-free copper (OFC) wires with twisted-pair or coaxial configurations to minimize signal loss and crosstalk.

- Insulation: PVC or PE (polyethylene) coating for electrical isolation and flexibility.

6. Additional Components

- Screws and Fasteners: Stainless steel screws to secure housing halves and connectors.

- Thermal Paste: Applied to IC chips for heat dissipation in high-bandwidth applications.

Key Material Advantages:

- Gold-Plated Contacts: Ensure corrosion-free, high-speed signal transmission.

- EMI Shielding: Maintains signal purity in environments with wireless devices or power cables.

- Durable Housing: Resists physical wear, heat, and environmental stress (e.g., humidity).

- RoHS Compliance: Lead-free and environmentally friendly materials meet global safety standards.

This meticulous selection of materials guarantees that HDMI male-to-female adapters deliver seamless connectivity, longevity, and compliance with HDMI standards, making them ideal for home theaters, gaming setups, and professional AV systems.

Quality

Certifications

The company has passed HDMl Adopter certification, Rohs, CE,REACH and more than 10 patented technologies, providing customers with security in technology and quality.

Why Choose Us as Your Converter Manufacturer Partner

Finding the right converter manufacturer to meet your project’s specific needs can be challenging. At our factory, we prioritize your goals with tailored solutions, uncompromising quality, timely delivery, and dedicated support. Here’s how we go the extra mile to make sure you get exactly what you need from your converter provider.

Tailored to Your Needs

We know that one size doesn’t fit all, especially when it comes to converters. As your converter manufacturer, we specialize in designing and producing custom converters that fit your unique requirements perfectly. Whether you need specific configurations, unique features, or branded finishes, we work closely with you to create products that seamlessly align with your project needs. With us, you won’t have to settle for “almost right”—you’ll get the exact converter that enhances your operations.

High-Quality Assurance

Quality is at the core of everything we do. Our manufacturing process follows stringent quality standards to ensure that each converter meets the highest levels of performance and durability. By partnering with us as your converter manufacturer, you’ll benefit from converters crafted with premium materials, cutting-edge technology, and rigorous testing. We don’t just meet industry standards—we aim to exceed them, giving you converters that you can trust in even the most demanding applications.

Fast Turnaround Times

We understand that timing is critical for your projects, and unexpected delays can lead to costly setbacks. That’s why we’ve structured our production processes to ensure efficient and timely delivery, without compromising on quality. Whether you need prototypes or a large production run, as a reliable converter manufacturer, we’re committed to keeping your projects on schedule by delivering the converters you need, exactly when you need them.

After-Sales Support

Our support doesn’t stop after delivery; we’re here to assist with any questions or challenges that may arise. From installation to troubleshooting, our dedicated after-sales team is ready to help ensure that your converters perform optimally. By choosing us as your converter manufacturer, you’re not only gaining a supplier but a long-term partner who is committed to your success.

Converter factory FAQs

What types of converters does your factory manufacture?

Our converter factory specializes in a variety of converters, including USB to SATA, HDMI, VGA, and other interface solutions for data transfer and display applications. If you need a specific type, feel free to reach out to us.

Can I request custom converter specifications?

Absolutely! As a flexible converter factory, we offer customized solutions to match your unique requirements, including specific dimensions, functions, and designs. Our team works closely with you to ensure the converter meets your standards.

What quality standards do your converters meet?

Quality is a top priority at our converter factory. Each converter undergoes rigorous testing and adheres to international standards such as CE, FCC, and RoHS, ensuring high performance and reliability across all applications.

How long is the typical production lead time?

Our standard lead time varies depending on order size and complexity, typically ranging from 7-15 days. As a customer-focused converter factory, we prioritize efficient production to meet your deadlines whenever possible.

Do you provide after-sales support?

Yes, we offer comprehensive after-sales support to address any issues or questions that may arise. As your converter factory partner, we’re committed to ensuring your continued satisfaction with our products.

How do I place an order or request a quote?

To place an order or get a quote, simply contact us through our website or email. Our sales team at the converter factory will guide you through the process and provide a detailed response within 24 hours.

Generally, there are stocks of common Converters or raw materials in our warehouse. But if you have special demand, we also provide customization service and design your own Converter housing. We also accept OEM/ODM. We could print your logo or brand name on the housing of Converter and color boxes.

Free samples available. Click the button below to get a quote!

OEM/ODM Manufacturing — Bringing Your Ideas to Life

Boost your brand visibility by launching converters with custom designs and logos. Whether you have a fully developed concept or a rough idea, our adaptable customization options, expert craftsmanship, and extensive industry experience will transform your vision into reality. Leverage our professional OEM/ODM services today.

STEP 1: Define Customer Requirements

We start by thoroughly understanding the customer’s needs, including color preferences, functionality, logo printing, and custom packaging, ensuring that the final product matches their vision precisely.

STEP 2: Feasibility Study

We conduct a detailed feasibility study of the project and, once confirmed, present an initial product design. If the project passes the feasibility check, we proceed to the next stage.

STEP 3: 2D, 3D Design & Sample Approval

In this phase, we create the initial product design based on customer specifications and develop 3D samples. These designs and samples are sent to the customer for feedback and final approval.

STEP 4: Mold Creation

Upon approval of the 3D sample, we move forward with mold development. Rigorous testing is carried out to ensure the product’s performance and reliability. Any necessary adjustments are made until the customer is satisfied with the final result.

STEP 5: Final Product & Mold Confirmation

We provide 3 to 5 PP samples for the customer’s final verification. Once confirmed, both the product and mold are ready for full-scale production.

Contact Us

Get in Touch for Your Custom Solutions!

Have specific requirements or technical questions? Our team is here to assist you. Fill out the form below, and one of our experts will reach out to provide the perfect solution tailored to your needs. Experience fast, reliable service with us!